Rice University bioengineers have developed an advanced technology that has the potential to eradicate the problem of missing crucial doses of medicines and vaccines. The technology involves creating time-released drugs that can be administered in a single shot and provide effective treatment for chronic diseases for an extended period.

Kevin McHugh, the corresponding author of the study published in Advanced Materials, emphasized the significance of this breakthrough technology in addressing the issue of medication non-adherence.

He said that “Around half of the people don’t take their medicines as instructed, and it’s a significant concern when it comes to treating chronic illnesses. With this new technology, patients would receive just one injection and would be well-treated for the next several months.”

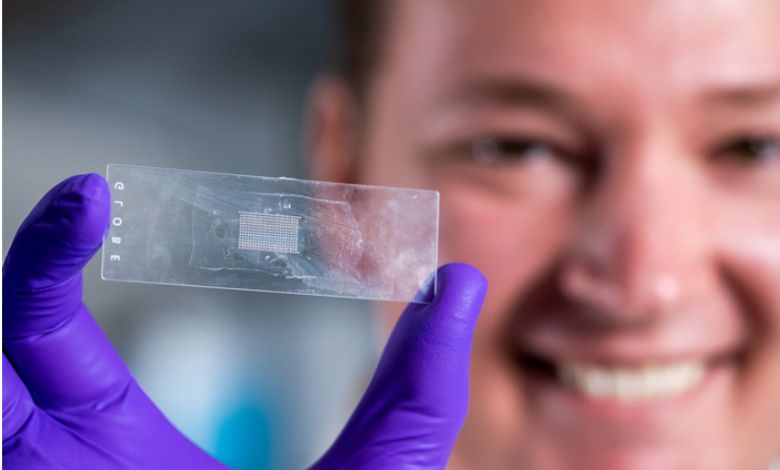

In their study, published in Advanced Materials, Kevin McHugh and graduate student Tyler Graf used 21st-century techniques to develop a new encapsulation technology called PULSED (short for Particles Uniformly Liquified and Sealed to Encapsulate Drugs).

The technology employs 3D printing and soft lithography techniques. It uses these techniques to create arrays of small, nontoxic, biodegradable cylinders. Standard hypodermic needles can inject these cylinders due to their small size. The cylinders are made of a polymer called PLGA, which is commonly used in medical treatment.

They demonstrated four methods of loading the microcylinders with drugs and showed they could tweak the recipe to vary the speed at which the particles dissolve and release the drugs from as little as 10 days to almost five weeks.

The team hopes this technology could be used to produce pulsatile-release particles to deliver vaccines and provide a reliable way to set the delayed timing of the release. The cylinders are made of PLGA, a widely used polymer in clinical medical treatment. They also developed a fast and easy method for sealing the cylinders, which is a critical step in time-release drug delivery, overcoming the uneven dosing that’s characteristic of current methods of drug encapsulation. The contactless sealing method happened partly by chance, and this discovery could also reduce the cost of production for many applications.

The new technology of time-released drugs has the potential to deliver large or continuous doses of drugs to a specific location, such as a cancerous tumor. By providing a prolonged, concentrated dose of the drugs exactly where they’re needed, could make chemotherapy more effective and reduce its side effects.

PULSED technology has immense potential for various applications and can bring a revolutionary change in drug delivery. Not only chronic disease treatment and vaccine delivery but also chemotherapy can utilize it to administer concentrated drug doses directly to tumors.

McHugh and Graf’s work on PULSED is just one example of the exciting advances being made in bioengineering, which are transforming the way we approach healthcare. In the coming years, we can anticipate seeing more groundbreaking solutions to long-standing medical challenges. This will be due to more researchers exploring advanced technologies, such as 3D printing, to develop new drug delivery methods.

PULSED technology marks a significant advancement in time-released drug delivery, which could provide a solution to a major challenge in treating chronic illnesses. With PULSED, patients can receive a single injection that could last for months, which could help improve patient adherence to treatment plans and lower healthcare expenses.

McHugh pointed out that the PULSED technology could be used for more than just drug delivery. It could also help distribute vaccines in countries with limited resources. Moreover, due to its adaptability and capability to be customized for precise release profiles, PULSED has the potential to bring significant change to the healthcare sector in the future.